AZA Power Systems

About the Company

Aza was founded by two faculty at the University of Minnesota and spun out in early 2023 to become a leader in ammonia technologies. Aza holds intellectual property and hardware technologies for ammonia combustion in generators, engines, and thermal applications (power turbines and industrial heat). Ammonia is a complementary fuel to hydrogen and, together, opens many pathways to industrial decarbonization. Aza technologies enable internal combustion engines and generators, with outputs up to 3 megawatts, to run on 100% ammonia. Aza focuses on products used in backup power generation (remote power, data centers, server farms), maritime (short haul), industrial heat, and mining and construction.

Innovators Network Partners

Aza is exploring a demonstration project with the Center for Microgrid Research at the University of St. Thomas.

About the Technology

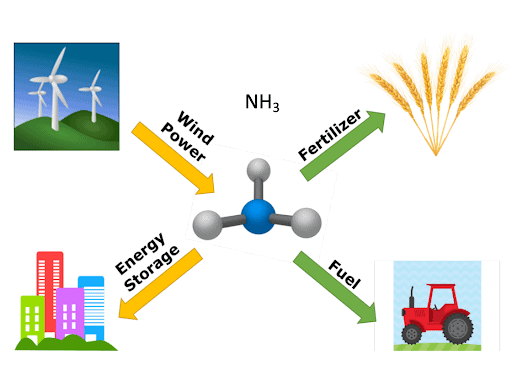

Ammonia can be combusted in internal combustion engines similar to diesel and natural gas, but without any carbon emissions. Ammonia is a flexible alternative fuel, with many roles to play in a net-zero world. It can be stored indefinitely at low cost, transported by container or pipeline, and is available almost anywhere worldwide. For energy, ammonia can be combusted directly or converted into hydrogen, depending on the use case. Aza focuses on the former, which offers a more efficient pathway to utilizing ammonia’s energy.

Carbon-intensity of ammonia production varies globally, but ammonia can be produced quite readily from renewable electricity. This zero carbon intensity ammonia, sometimes referred to as “green,” is ideal for Aza’s technologies as it means no carbon is emitted from start to finish. Green and decentralized ammonia production technologies are seeing increased popularity, especially with rural cooperatives, and may pave the way for a larger green ammonia/hydrogen economy.

Conversion to pure ammonia combustion can be performed on either compression-ignition or spark-ignition engines. Aza’s technologies blend the best qualities of both ignition modes to achieve clean combustion and high power output. For spark ignition, when using ammonia alone, a low Laminar flame speed is needed. Additionally, H2-NH3 blends from cracking are promising, but have reduced volumetric efficiency.

Innovators Network Partners

Aza is exploring a demonstration project with the Center for Microgrid Research at the University of St. Thomas.

About the Technology

Ammonia can be combusted in engines similar to diesel and natural gas, but without the carbon emissions. The flexibility of ammonia combustion is through leveraging existing infrastructure and distribution systems, reducing costs and ease of transition to the fuel source. Ammonia can be combusted directly or converted into hydrogen, depending on the use case.

The source ammonia can vary, but Aza is seeking opportunities to utilize green ammonia, produced from renewable sources, or other carbon-neutral alternatives. Rural green ammonia has promise to decarbonize agriculture and be part of a green hydrogen economy.

Ammonia can be used in both compression ignition and spark-ignited engines. Within a compression ignition, 100% NH3 requires a high compression ratio (CR > 35:1), offers dual-fuel strategies, and approximately a 5% diesel injection for low-speed engines. For spark ignition, when using ammonia alone, a low Laminar flame speed is needed. Additionally, H2-NH3 blends from cracking are promising, but have reduced volumetric efficiency.